JULY 24, 2025

POSTED BY:

BEN SCHLEUNIGER,

CEO & CO-FOUNDER,

ORBITAL OPERATIONS

“It’s a new kind of capability—one that brings maneuver warfare, rapid repositioning, and orbital presence to national security space. And to earn its place, it has to work on day one. This roadmap is how we make sure it does.”

“It’s a new kind of capability—one that brings maneuver warfare, rapid repositioning, and orbital presence to national security space. And to earn its place, it has to work on day one. This roadmap is how we make sure it does.”

Straight to the point

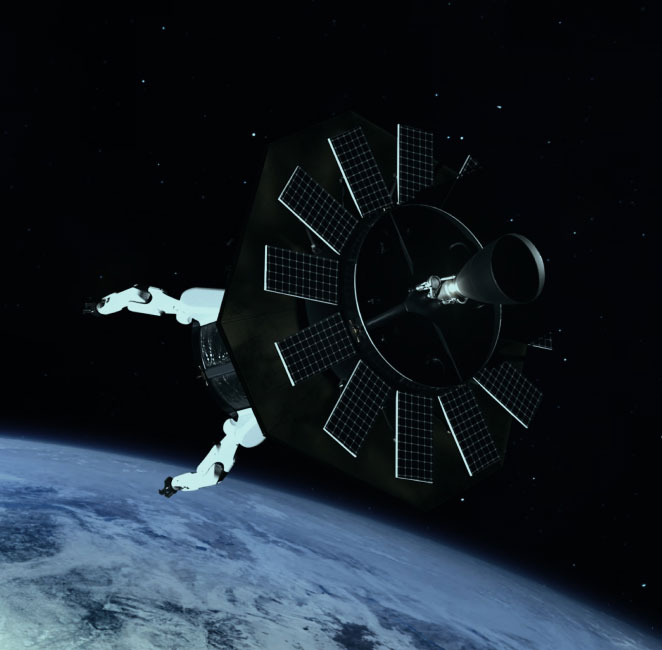

Astraeus is the vehicle we’re building to fundamentally change how space operations are conducted. It’s designed to deliver high thrust, stay on station for years, and refuel in orbit, all while being ready to move and respond at a moment’s notice.

Getting there isn’t about racing to launch a single prototype. It’s a methodical, systems-first process: proving out each core technology, validating our architecture step by step, and showing both government and commercial partners that we can deliver real performance on real timelines.

This post walks through the major milestones ahead of us and how each one brings us closer to putting a fully operational Astraeus vehicle on orbit.

What Astraeus actually is

At a systems level, Astraeus is a cryogenic orbital maneuvering vehicle. It runs on a 15,000 lbf LH₂/LOX engine and is built around our custom Cryogenic Propellant Management System (CPMS), which allows it to loiter for years in space with active cooling and in-orbit refueling.

This kind of persistent, high-thrust mobility doesn’t exist today. To get there, we’re developing and validating the system in phases, building up from ground demonstrations to full orbital capability.

Where we are now

We’re currently deep in CPMS prototyping and engine development. These are the two core technologies that unlock everything else Astraeus can do. Our seed round is funding two key technical goals:

- A full-scale, pressure-fed chamber hotfire of our engine

- Operational demonstrations of both the 90 K and 20 K cryogenic systems for propellant storage and conditioning

The chamber hotfire is scheduled for the end of Q4 2025. This test kicks off our propulsion qualification campaign by validating injector design, combustion stability, and overall performance at full scale.

In parallel, we’re running cryogenic system development. The CPMS features two temperature stages:

- The 90 K stage, which removes the bulk of the heat for both the hydrogen and oxygen systems

- The 20 K stage, dedicated specifically to liquid hydrogen

Each one requires its own fluid architecture, insulation, and heat rejection system.

Key Milestones

- Q1 2026: FIRST 90 K CPMS TEST

This test validates our ability to manage oxygen temperatures in space-like conditions. It’s where we dial in heat exchanger design, radiator performance, and basic flow control at cryogenic temps. It moves significantly more heat than the inner system but is actually the easier of the two due to its higher temperature range. - Q2 2026: FIRST 20 K CPMS TEST

This is the more demanding milestone. Hydrogen is extremely cold. This test pushes our insulation stackups, heat lift hardware, and compressor cycle design to flight-representative conditions.

These aren’t just technical checkmarks. They’re the foundation of long-duration mobility. If the cryo system doesn’t work, nothing else does.

Building toward the orbital demo

Once we’ve validated the CPMS on the ground, we move to a critical step: running it in space. Our Orbital Demo Vehicle will carry all of the core subsystems of Astraeus except for the engine. It’s a pure cryo mission focused on proving long-term hydrogen and oxygen storage in the space environment.

The vehicle will include tanks, chillers, compressors, heat exchangers, radiators, avionics, and a simulated feed system. This is our path to flight heritage and the last major milestone before engine integration.

Key Milestones

- Q1 2027: ORBITAL DEMO QUALIFICATION COMPLETE

All hardware passes functional, thermal, and vibration testing. Ready for integration and shipment. - Q2 2027: ORBITAL DEMO SHIPPED

The vehicle launches to orbit and begins its extended cryogenic operations campaign. We’ll collect thermal data, assess fluid behavior, and refine our control logic with flight telemetry.

The integrated vehicle comes next

While the orbital demo is in flight, we continue propulsion development in parallel. The next major step is our first fully integrated hotfire of the Astraeus engine, using flight-like components including the turbopump, injector, chamber, regenerative cooling, and engine controller.

Key Milestones

- Q2 2027: FIRST FULLY INTEGRATED HOTFIRE

The full engine stack is fired at operational conditions. This test validates thrust performance, combustion stability, and the flight control system. - Q2 2028: ENGINE QUALIFICATION COMPLETE

With full-duration firing and repeated testing, the engine is declared flight ready.

Final vehicle and first flight

With engine and CPMS both qualified, we integrate the complete Astraeus vehicle. This includes avionics, propulsion, power, software, and the entire fluid system stack.

Key Milestones

- Q3 2028: ASTRAEUS QUALIFICATION COMPLETE

The vehicle undergoes integrated hotfire, vibration, thermal vacuum, and full environmental testing. - Q2 2029: ASTRAEUS DEMO MISSION

This is the final step. We go to orbit, maneuver, and light the engine in space. The mission proves we can deliver high-thrust, long-duration mobility on demand.

Why this matters

Each step on this roadmap is intentional. We’re building a system that has to operate far from Earth, for long durations, with no opportunity for repair. There’s no margin for error and no room for shortcuts.

Astraeus isn’t just a propulsion platform. It’s a new kind of capability—one that brings maneuver warfare, rapid repositioning, and orbital presence to national security space. And to earn its place, it has to work on day one.

This roadmap is how we make sure it does.

If you’re an engineer who wants to work on the real stuff—the engine burns, the flight hardware, the deep cryo thermal cycles—we’re hiring.