July 21, 2025

POSTED BY:

BEN SCHLEUNIGER,

CEO & CO-FOUNDER,

ORBITAL OPERATIONS

“If we wanted to move fast, launch soon, and deliver a high-performance space vehicle that could maneuver like nothing else in orbit, we had to go back to rocket propulsion fundamentals. And those fundamentals pointed to LH2/LOX.”

“This isn’t theoretical. We’re building a system with high thrust, long duration, and in-space refuel capability all in one package. That’s what makes Astraeus different.”

Straight to the point

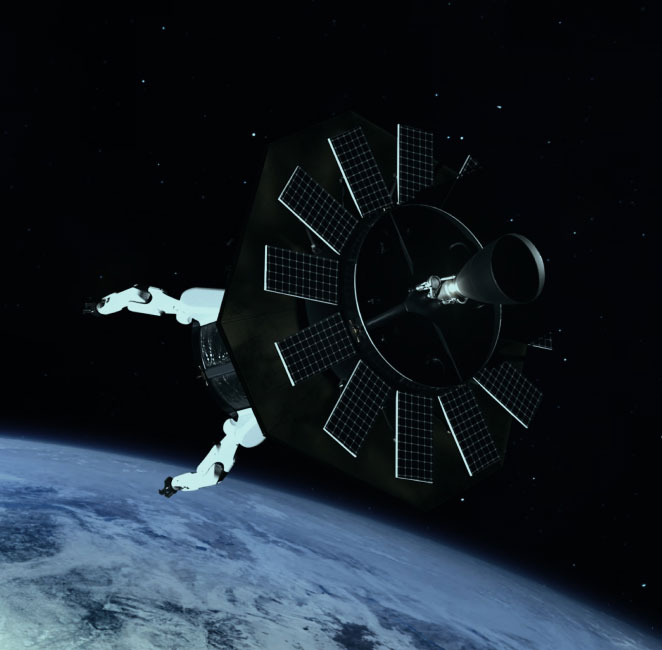

At Orbital Operations, we’re building a high-thrust space vehicle designed to move fast and defend satellites in orbit. It’s called Astraeus. The vehicle has evolved a lot since its inception, but one decision locked in early: we went with liquid hydrogen and liquid oxygen for our propulsion system.

That raised some eyebrows. Hydrogen is tough to work with. It boils off quickly, it seeps through everything, and the cryogenic systems push aerospace designing and manufacturing to the edge. But all of that is worth it for what we got in return: efficiency, thrust, and a path to real long-duration capabilities in space.

This post is about why we made that call, and why it’s one of the most important decisions we’ve made.

How we got here

The idea of using liquid hydrogen didn’t come about from following the typical “optimize for rocket performance” path. Before Orbital Operations, I was helping another startup explore nuclear thermal propulsion. The concept was simple: heat hydrogen with a nuclear reactor, shoot it out the back, and get 1000 seconds of specific impulse. On paper, it looked like the future of deep space mobility.

But it became clear how stacked the technical deck was. A nuclear engine introduces a mountain of new engineering and regulatory challenges. On top of that, you still need to store and manage liquid hydrogen, which is its own mess. We pivoted to ammonia for easier handling, but performance dropped by more than half. Suddenly we were solving all the hardest parts of nuclear propulsion just to end up at the same efficiency that liquid hydrogen and oxygen already provide today.

That was when I stopped chasing new propulsion methods and started focusing on enabling what already works.

If we wanted to move fast, launch soon, and deliver a high-performance space vehicle that could maneuver like nothing else in orbit, we had to go back to rocket propulsion fundamentals. And those fundamentals pointed to LH2/LOX.

Hydrogen benefits

Liquid hydrogen isn’t trendy. It’s not easy. But when you weigh all the options, it wins.

SPECIFIC IMPULSE

- Liquid hydrogen gives you the highest efficiency of any chemical propellant. Our engine will run at 450 seconds of Isp, which gives Astraeus over 10 km/s of delta-v. That means we can reposition and intercept across a greater range than any other chemical system that fits inside a Falcon 9 payload fairing. This kind of maneuverability is what allows us to defend something in space, not just observe it.

- The math is simple. Propulsion is about kinetic energy. The more velocity you can impart on your exhaust, the more equal and opposite force you get on the vehicle. Since KE = ½ * mass * velocity², you always want to maximize velocity. In thermal or chemical systems, that means accelerating smaller molecules. Hydrogen, being the lightest, is the clear winner.

HIGH THRUST

- This applies to any pump-fed propulsion system, and LH2/LOX is one of them. We’re building a 15,000 lbf engine, which is about 20 times the thrust of even the highest-power systems currently operating in orbit. The thrust-to-weight ratio scales nearly linearly, unlike many other systems that quickly run into exponential mass penalties from supporting hardware. That scalability will give us options as we iterate.

REFUELING WITH WATER

- One of the biggest hidden advantages of LH2/LOX is that you can make it from water. That wasn’t the reason we picked hydrogen, but it’s a huge bonus. We can launch stable water tanks to orbit, use electrolysis to split the water into hydrogen and oxygen, and then condense those gases into cryogenic propellants. It takes time (about two months for a full refuel) but once that system is in place, you can dock and top off without waiting for a launch. That changes the logistics game entirely.

FUTURE COMPATIBILITY WITH NUCLEAR

- If the industry ever gets serious about nuclear propulsion, it’s going to use hydrogen. Everything we’re building now (chillers, storage, feed systems) is not only mission-critical for Astraeus but sets us up for whatever comes next.

This wasn’t just about picking a high-performing propellant. It was about building something that lasts. Something we can refuel, redeploy, and rely on across orbits and across missions. Hydrogen is how we get there.

What we’re actually building

The engine cycle isn’t the hard part. It is hard, but it isn’t new. The hard part is keeping hydrogen cold and stable for years while the vehicle loiters in orbit, ready to move. That’s where our Cryogenic Propellant Management System comes in.

Without active cooling, liquid hydrogen would boil off and vent out of the tanks in a matter of days. We’d lose all our delta-v just sitting there. Our CPMS uses advanced compressors, turbo-alternators, and heat exchangers to keep the tanks cold and the pressure stable for extended durations. That system is the backbone of Astraeus’ endurance.

We’re also solving for the plumbing itself. Hydrogen is a tiny molecule. It leaks through seals, creeps through welds, and stresses valves in ways most people don’t want to deal with. But if you solve it, and we are, you unlock a propulsion architecture that nothing else can match.

This isn’t theoretical. We’re building a system with high thrust, long duration, and in-space refuel capability all in one package. That’s what makes Astraeus different.

What this enables

So let’s say Astraeus is done and we have a working cryogenic propellant management system for liquid hydrogen. What do we actually get?

We get the equivalent of a third stage rocket in orbit; one that never comes back down. It has the highest efficiency of any space-based chemical propulsion system, paired with full-scale launch vehicle thrust. That lets us respond to threats in orbit or even intercept ballistic objects that apogee above the atmosphere. For those targets, response time isn’t hours. It’s minutes. Having that thrust matters.

We also get water refueling. This wasn’t part of the original concept, but once we committed to hydrogen, it became obvious.

Instead of launching cryogenic propellants directly, we can send up a single water tank with enough mass to refuel multiple vehicles. It’s cheaper, safer, and more stable. Once in orbit, we use electrolysis to split the water. The gases naturally self-pressurize, which means we avoid having to pump liquids in zero-g. Hydrogen and oxygen then feed into our cryogenic system and condense over time.

Yes, it takes a few weeks. But once it’s ready, that tanker becomes a permanent refuel station in LEO. No launch coordination. No windows to hit. Just dock, refill, and go—all from a low-maintenance orbital platform. If we’re going to go all-in on performance with our vehicle, then we’re going to take the win on a simpler refueling station.

This is how you create persistence in orbit. And it only works because of what we’ve built around hydrogen.

Looking ahead

Choosing hydrogen wasn’t a shortcut. It was a strategic move to build the foundation for space defense and orbital mobility. Astraeus doesn’t just launch and burn. It lives in orbit. It waits, watches, and responds.

Liquid hydrogen is what makes that possible.

If you’re an engineer who wants to solve some of the hardest cryogenic problems in aerospace, or someone who wants to make real systems that move at mission speed, we’re hiring.